Fig.1.

Fig.1. Fig.2.

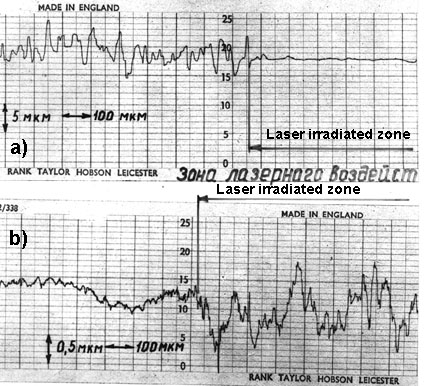

Fig.2.Quasi-equilibrium roughness with Ra = 0.2 μm forms during laser heat treatment without melting (the zone of 2 - 6 pulse in fig.1, surface of the spot - fig.2). Topography of the surfaces change because of micromelting of the asperities. On further irradiation, the roughnessincreases and reaches proper equilibrium one (fig.1).

Also other data on the parameters of the quasi-equilibrium and equilibrium roughness are given in [1] (mean spacing of profile asperities, mean asperity peak curvature radius, parameters of bearing curve power approximation, etc). Mechanisms leading to formation of quasi-stationary roughness and the subsequent transformation to stationary one were discussed in [1] also.

Fig.1. Fig.1. |  Fig.2. Fig.2. |

Fig.3. Fig.3. |